Cracks due to drying or thermal movement

Both the drying processes and thermal movement (e.g. due to the commissioning of the heating system) may lead to crack formation over the screed cross-section. Such failures occur where the internal tensile strength of the cured mortar is exceeded. The cracks normally run across the entire thickness of the slab, which it divides into two. The bonding of ceramic tiles over damaged substrates of this kind is not advisable without prior crack repair. Otherwise, the two parts of the screeds slab will work against each other when loaded and bring about fracture of the tiles at the position of the underlying crack.

Solid floor insulation

In the case of solid insulation, sections must not only be glued but also correctly joined using dowels. Vertical loads transmitted via dowel will avoid movement and help prevent cracking. It is very common for solid floor insulation to be installed without correctly glueing or doweling which is a common cause of cracking.

Avoid cracking with expansion joints

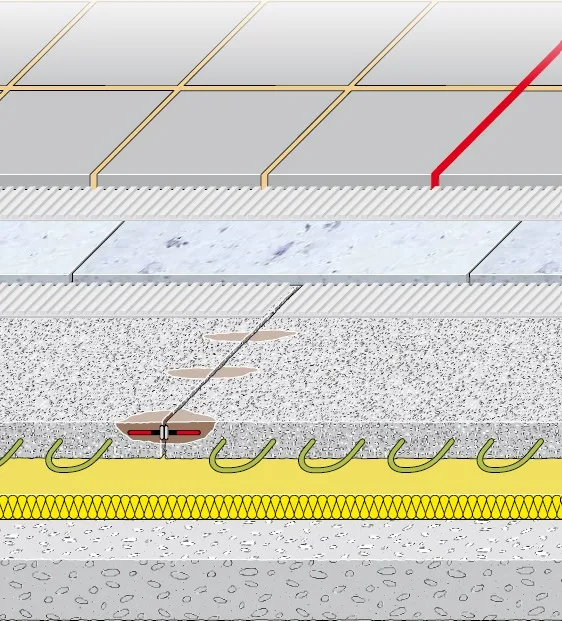

Resin-filling and recutting of joints for unheated screeds (CA and CT)

The standard solution adopted on-site for unheated cementitious and calcium sulphate screeds involves the application of resin to fill the existing movement joints. The existing bay joint is cross-dowelled (with corrugated-metal dowels) and resin-filled (Sopro RH 646 crack resin, Sopro GH 564 casting resin, Sopro SH 649 shaken resin) to create a structurally continuous bond. Prior to flooring installation, a new bay joint is cut at the appropriate position across the entire screed and carried through the floor covering along the same line. Here, the maximum screed bay sizes specified in the data sheets should be observed.

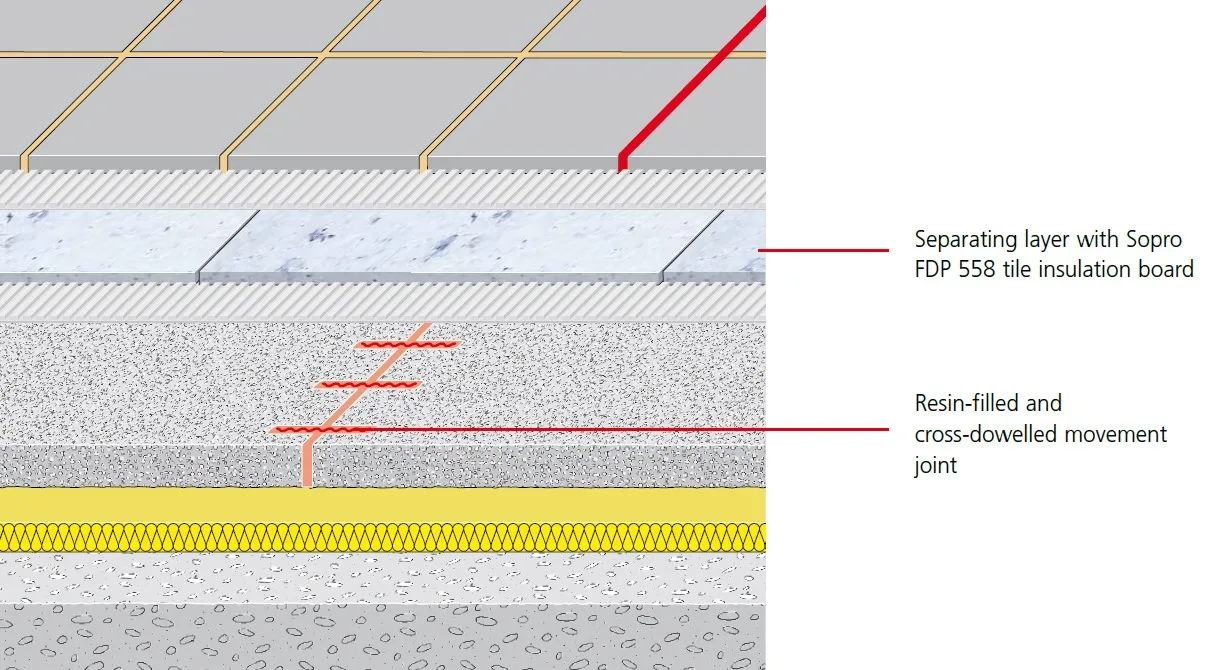

Bridging of bay joints in heated screeds with protection against vertical displacement and incorporation of separating layer

It is possible to adopt different movement joint positions for floor covering and heated screed through the incorporation of Sopro EDD 152 screed expansion dowels in the movement joint – to prevent vertical displacement – followed by the installation of a separating layer below the floor covering.

The movement joint thus allows free horizontal movement and continues to accommodate any changes in length. The Sopro EDD 152 dowels are fixed at approx. 30 cm centres and structurally bonded with Sopro DBE 500 epoxy tile adhesive. The installation depth depends on the cover over the heating pipes, though should be no less than 2 cm.

The separating layer (4 mm/7 mm Sopro FDP 558 tile insulation board) is then installed on the stabilized screed surface. All layers should be bonded using S2-grade adhesives (Sopro MG 669/Sopro MG 679 or Sopro

MEG 665/Sopro MEG 666). The movement joints in the tile covering (positioned to match the tile joint pattern) should run parallel to the bridged screed bay joints. A spacing of

approx. 8 – 10 m should be observed.

Even with heated screeds, it is possible to adopt different movement joint positions for substrate and floor covering through the use of a separating layer (Sopro FDP 558 tile insulation board), a safeguard against vertical displacement (Sopro EDD 152 screed expansion dowels) and highly flexible S2-grade adhesives (e.g. Sopro MEG 665).

Repair

To restore the monolithic connection between the two parts of the screed, the cracks must first be mechanically enlarged (with an angle grinder), and then grouted with resin to create a structurally continuous bond. Cross-dowels must be inserted along the length of the crack at 25 – 30 cm intervals. In the event of cork screeds this can be done with a cork repair screed. Note: Where heating systems are installed, particular care must be taken to prevent damage to heating wires or tubes.

Reaction resin (Sopro GH 564) poured into crack to create structurally

continuous bond between two parts of screed.

Repaired cracks, with special cross-dowels incorporated at approx. 25 – 30 mm intervals and ground down if needed.