wood drying with a Vacuum kiln

Wood drying is an essential part of the woodworking process, as it ensures that the wood is stable, sturdy, and free from moisture. Traditionally, wood has been dried using kilns that rely on heat and airflow. However, advancements in technology have introduced a more efficient and effective method – vacuum kiln drying. In this article, we will explore the numerous advantages of drying wood in a vacuum kiln compared to a traditional kiln, discussing the process, benefits, potential drawbacks, and the future of wood drying technology.

Understanding the process of wood drying

Before delving into the advantages of vacuum kiln drying, it’s important to have a basic understanding of the wood drying process. When wood is harvested, it contains a significant amount of moisture. This moisture must be removed to prevent the wood from warping, cracking, or shrinking. Traditional kiln drying involves exposing the wood to high temperatures and circulating air, which accelerates the moisture evaporation process. Vacuum kiln drying, on the other hand, relies on the principle of lowering air pressure to facilitate the moisture extraction process.

Wood drying is a crucial step in the timber processing industry, ensuring that the wood is stable and ready for use in various applications. The process not only removes moisture but also improves the wood’s strength and durability, making it suitable for construction, furniture making, and other purposes.

The science behind wood drying

Wood is hygroscopic, meaning it naturally absorbs and releases moisture. Vacuum kiln drying takes advantage of this property by creating a low-pressure environment. When pressure is reduced, water molecules inside the wood start to vaporize at lower temperatures than in a traditional kiln. This lower temperature results in less degradation of the wood’s cell structure, leading to improved overall wood quality.

Furthermore, the controlled environment of a vacuum kiln allows for more precise monitoring and adjustment of drying parameters, ensuring consistent results and minimising the risk of defects such as checking, splitting, or case hardening.

Traditional kiln drying versus vacuum kiln drying

While traditional kiln drying has been the industry standard for many years, vacuum kiln drying offers several significant advantages. One of the main differences lies in the speed and efficiency of the drying process.

Vacuum kiln drying also has the added benefit of being more environmentally friendly, as it requires less energy and produces fewer emissions compared to traditional kiln drying methods. This makes it a more sustainable option for businesses looking to reduce their carbon footprint and operate in an eco-conscious manner.

The benefits of vacuum kiln drying

Efficiency and speed of vacuum kiln drying

One of the most notable advantages of vacuum kiln drying is its efficiency. By reducing the air pressure, vacuum kilns can dry wood at a much faster rate compared to traditional kilns. This increased speed not only saves time but also reduces energy consumption. Additionally, vacuum kilns are highly effective in evenly drying the wood, minimizing the risk of uneven drying and associated defects.

Furthermore, the use of vacuum kiln drying technology allows for a more precise control over the drying process. This level of control enables operators to tailor the drying conditions to specific wood species and moisture content requirements, resulting in a more customised and efficient drying process.

Quality of wood dried in a vacuum kiln

Vacuum kiln drying also offers superior wood quality compared to traditional kiln drying methods. The reduced temperature in a vacuum kiln significantly reduces the potential for case hardening, surface checking, and other common defects that can occur during traditional kiln drying. The slower drying process allows the wood to maintain its dimensional stability and structural integrity, resulting in a more durable and reliable end product.

In addition to the improved quality of the wood, vacuum kiln drying can also enhance the aesthetic appeal of the final product. The controlled drying environment helps to preserve the natural colour, texture, and grain patterns of the wood, leading to a more visually appealing finish that showcases the inherent beauty of the timber.

Environmental impact of vacuum kiln drying

With sustainability becoming an increasingly vital consideration, vacuum kiln drying presents a more environmentally friendly option. By operating at lower temperatures and utilizing advanced moisture monitoring systems, vacuum kilns have a significantly reduced carbon footprint compared to traditional kilns. The efficient and controlled drying process also minimizes waste and ensures a more sustainable use of resources.

Moreover, the use of vacuum kiln drying technology can contribute to the conservation of forests and natural habitats. By reducing the drying time and energy consumption, vacuum kilns help to lower the demand for freshly harvested wood, thereby promoting responsible forestry practices and supporting the preservation of ecosystems.

Potential drawbacks of traditional kiln drying

Time consumption in traditional kiln drying

One drawback of traditional kiln drying is the time it takes to complete the process. Depending on the type and thickness of the wood, drying times can range from several weeks to months. This extended duration can be a significant disadvantage, especially in industries that require quick turnaround times.

Furthermore, the prolonged drying period can also increase the risk of fungal growth or decay in the wood, impacting its quality and market value. This risk highlights the importance of efficient and timely drying methods to maintain the integrity of the wood.

Quality concerns with traditional kiln drying

Traditional kiln drying methods may lead to various quality concerns. The high temperatures used can cause wood to dry too quickly, leading to stress-related issues such as warping, splitting, or checking. These defects can compromise the overall quality and usability of the wood, resulting in higher costs and potential customer dissatisfaction.

In addition, the uniformity of drying in traditional kilns can be challenging to achieve, leading to inconsistencies in moisture content throughout the wood. Variations in moisture levels can affect the wood’s dimensional stability and mechanical properties, impacting its suitability for different applications.

Environmental considerations of traditional kiln drying

Traditional kiln drying relies on burning fossil fuels to generate the required heat, contributing to greenhouse gas emissions and environmental pollution. Additionally, the use of chemicals and preservatives to prevent the growth of mold and pests can further harm the environment and pose health risks.

Moreover, the energy-intensive nature of traditional kiln drying processes not only increases operational costs for manufacturers but also places a strain on natural resources. Sustainable alternatives, such as solar kilns or vacuum kilns, offer more environmentally friendly options for wood drying, reducing the industry’s carbon footprint and promoting eco-conscious practices.

Making the switch to vacuum kiln drying

When considering the transition to vacuum kiln drying, it is essential to delve into the intricacies of assessing both the costs and benefits associated with this innovative technology. While the upfront investment in vacuum kilns may appear substantial, the long-term advantages cannot be overlooked. From significantly reduced drying times to the enhancement of wood quality and the notable decrease in energy consumption, the potential cost savings and improved profitability make a compelling case for making the switch.

Moreover, the environmental benefits of vacuum kiln drying should not be underestimated. By utilising this advanced technology, businesses can contribute to sustainable practices within the woodworking industry. The reduction in energy consumption not only leads to cost savings but also minimises the carbon footprint, aligning with the global shift towards eco-conscious manufacturing processes.

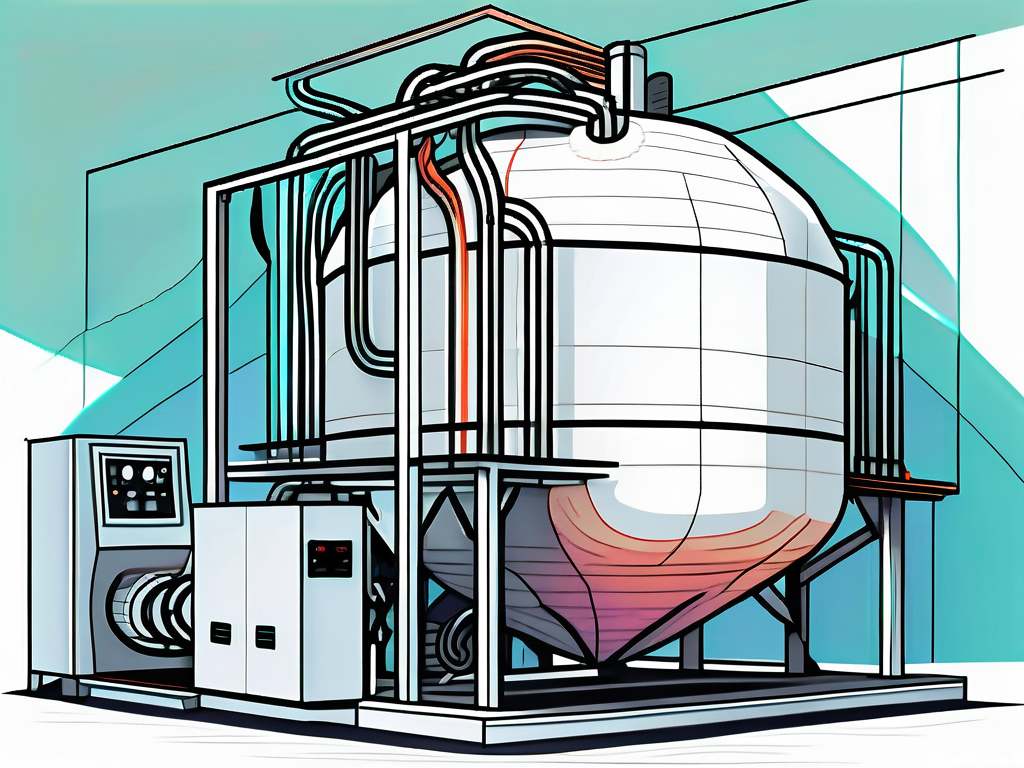

Necessary equipment for vacuum kiln drying

Embarking on the journey of vacuum kiln drying necessitates the acquisition of specialised equipment tailored to this cutting-edge method. Vacuum kilns are outfitted with an array of essential components, including precision vacuum pumps, moisture sensors for accurate readings, temperature controls to maintain optimal conditions, and sophisticated monitoring systems to track the drying progress. Investing in top-tier equipment and adhering to a stringent maintenance schedule are paramount in ensuring the efficiency and consistency required for successful vacuum kiln drying.

Furthermore, the integration of vacuum kiln drying into woodworking operations demands a meticulous approach to equipment selection. Each component plays a crucial role in the drying process, and the synergy between these elements is vital for achieving the desired results. By prioritising quality and reliability in equipment procurement, businesses can establish a solid foundation for seamless adoption of vacuum kiln technology.

Training and skills required for vacuum kiln drying

Transitioning to vacuum kiln drying necessitates more than just acquiring the right equipment; it also entails a commitment to training and skill development. Operators must undergo comprehensive training to grasp the nuances of the vacuum drying process, master the art of moisture content monitoring, and understand the behaviour of wood under varying conditions. Equipping personnel with the requisite knowledge and skills not only enhances operational efficiency but also minimises the likelihood of errors, unlocking the full potential of vacuum kiln technology.

Moreover, investing in continuous training and skills development cultivates a culture of expertise within the workforce, fostering innovation and driving excellence in vacuum kiln drying practices. By empowering employees with the necessary competencies, businesses can navigate the complexities of this advanced technology with confidence, paving the way for sustained growth and success in the woodworking industry.

The future of wood drying technology

Innovations in vacuum kiln drying

The future of wood drying technology lies in continuous innovative advancements in vacuum kiln drying. Researchers and manufacturers are constantly developing new techniques, equipment, and technologies to improve the efficiency, speed, and quality of the drying process. These innovations aim to further reduce energy consumption, enhance wood properties, and provide sustainable solutions for the woodworking industry.

Predicted trends in wood drying techniques

Predictions indicate that vacuum kiln drying will continue to gain popularity in the woodworking industry. As environmental concerns grow, vacuum kilns offer a more sustainable alternative to traditional drying methods. Additionally, advancements in control systems, real-time monitoring, and automation will further streamline the drying process, making it more efficient and convenient for woodworkers.

The role of vacuum kiln drying in sustainable woodwork

Vacuum kiln drying plays a crucial role in the pursuit of sustainable woodwork. By reducing energy consumption, minimizing waste, and improving wood quality, vacuum kilns contribute to the production of environmentally friendly and high-quality wood products. Implementing vacuum kiln drying techniques can help woodworkers meet sustainability goals while ensuring the durability and beauty of their finished creations.

Furthermore, the future of wood drying technology also holds promising developments in the field of moisture content measurement. Accurately determining the moisture content of wood is essential for ensuring its stability and suitability for various applications. Researchers are exploring innovative techniques such as near-infrared spectroscopy and electrical impedance to provide non-destructive and precise measurements of wood moisture content. These advancements will enable woodworkers to optimize their drying processes and produce consistently high-quality wood products.

In addition to moisture content measurement, advancements in vacuum kiln drying technology are also focusing on improving the control and regulation of temperature and humidity levels within the kiln. By fine-tuning these parameters, woodworkers can achieve optimal drying conditions for different wood species and thicknesses, resulting in minimized defects and improved overall quality.

At ECS, we operate three kilns. These kilns serve dual purposes: drying wood for our decorative walls and catering to the needs of other professional carpenters. For our mainstream wood, we employ a solar kiln during the summer months and resort to a traditional kiln during the winter. Subsequently, all wood undergoes the final drying process in our vacuum kiln, swiftly reducing moisture levels from 18% to 7% within a matter of days before shipment.